We’re continuing to try and work towards a more finished home, although it turns out that the stay-at-home order allows only for “essential” building work, nothing more. Obviously, that isn’t a problem for stuff we have in stock already. We can entertain ourselves as much as we like with the stuff we’ve got stored. It’s more of a problem for stuff we don’t have already – we aren’t allowed to order things like “deck boards”… Which makes some things we’d planned a little more tricky.

So. That being said we’ve continued with various other things that we have in stock, and some stuff we can mail-order, which is allowable. Unfortunately, there’s a bunch of jobs where I have managed to get half of the stuff required for any particular job. For example, I thought I had a router bit in that would suit my complex plan to make the trim for the windows and doors*, but I don’t. So although I have some trim oiled and ready to go, I don’t have the relevant tools to make it fit. Thankfully that’s at least small enough that when I’ve got around to checking what size bits our router takes, I can order it online.

But, that being said, we’ve still got several things done.

The gates for the south of the house, between the garage and the house, are built and up and functional.

You can really see the missing exterior trim on that picture, because we adjusted for the unsquareness of (most likely) the house and/or the panels in one big step that will be covered by trim boards. Irritatingly, I was two-boards short for my planned design, and obviously, I can’t get those until… May… at the earliest. Hence the half-arsed chunk that stops the gate flapping past the other gate, and the missing section on the left-hand gate at the bottom.

We also made the bookshelves for the sections above the door in the office and the bedroom. These were birch rather than beech, which we’ve decided was an error, but they’re well out of the way and will probably be so full as to be barely visible, so we’ve decided to ignore that problem.

And so it’s turning out, actually. Some decisions we made we’re not 100% convinced about. For example, our wall lights we have concluded are somewhat higher than we would ideally like (unfixable), and actually, we’re not convinced they go with the shades/height of the ceiling lights (fixable).

We have finally got the wall lights up, and it looks like we’ve managed to overcome the inch-and-a-bit drop in the floor towards the centre of the house with Kathryn’s clever concept.

The middle piece (the one with the large off-centre hole) allows us to adjust the position of the outer piece on the wall to provide a consistent space between the picture-rail and the light…

Which has allowed us to cover for the unsquareness. And actually, we’re really pleased with how they have come out – especially considering how cheap the lights were. We’re thinking though, that a simple white glass shade would actually work better than the industrial/enamel shades. Also something higher up. The enamel shades were chosen to tie the two ends of the room together, but it feels a bit of a clash between industrial and a sort of modern-trad look. Too busy.

Meh.

Sometimes you try something and it doesn’t work. The thing to remember in that situation is that you’re learning (not always easy to remember).

I’ve also moved the media server to the attic, which is pleasing. Less pleasing is the fact that I can’t find the 10-pack of Ethernet connectors, so I’m left with things hanging out of the wall. Bleh.

And I’ve been doing a little bit of tidying in the garden. I’ve mainly been just doing maintenance (strimming, mowing, weeding). But I’ve also slowly been filling in the trench with the pipe that carries water to the soak-away. That allows us to clear what will be the only veg bed that we’re planning to put in the ground (with a little bit of raising so we can put some decent topsoil on it). That will have to be prepared fairly soon because we’ve got some cabbages and tomatoes that will need to go out when it gets warm enough.

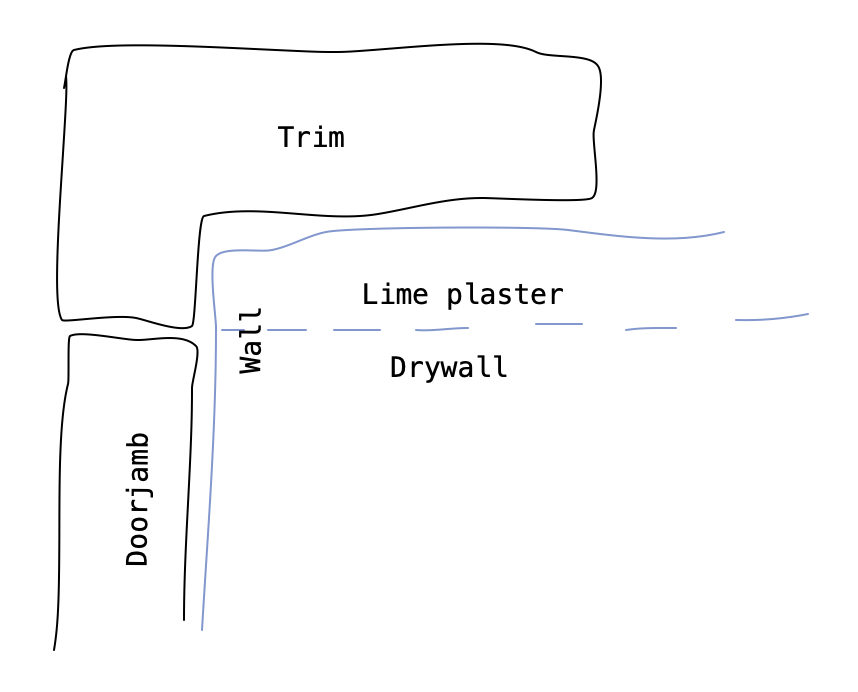

* Unfortunately, our walls, because of our non-standard wall coating, are not a standard thickness. Which means that we will need to make some L-shaped trim which will allow… oh, look, this would be easier with a diagram:

This is also true on the windows which ended somewhat recessed. Now the alternative is to get more expensive, thicker wood to replace the existing trim, plane it down (or run it through the thicknesser), and similarly, for the door jambs, buy a wider piece and shave it down with a plane to the right width, but that is upsetting because it’s (a) much more expensive, (b) wastes the existing wood trim which we paid for, (c) would end up with us having to saw/plane off nearly 1/2″ of wood, and (d) would be almost equally hard to get right.